In today’s world, sustainability is not just a trend but a necessity.

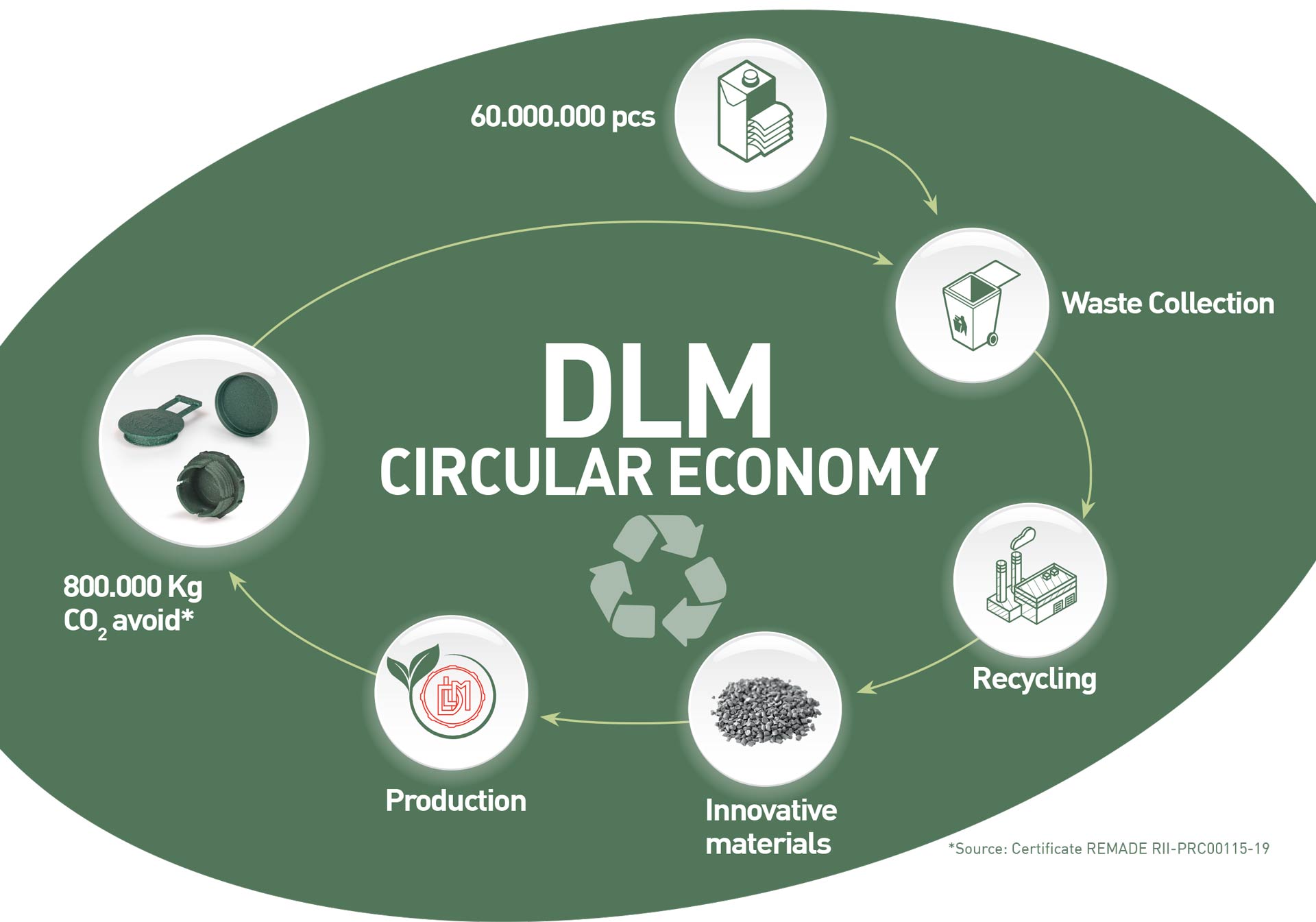

DLM TAPPI, an Italian company renowned for its expertise in thread protection systems, has embraced the principles of the circular economy with a revolutionary green approach.

This article explores how the company is making a significant impact in hydraulic, pneumatic, and automotive sectors with its innovative green solutions.

NEED MORE INFORMATION?

FIND OUT MORE ABOUT US

Circular Economy: From Theory to Practice

The circular economy is often viewed as a concept filled with theory but lacking practical implementation. Many see it as labor-intensive and not cost-effective.

However, DLM TAPPI’s story is quite the opposite. Founded in 1987 in Opera, near Milan, by Antonio Montanari, the company began by producing hydraulic bows and soon expanded its expertise to polymeric plastic caps used to protect threads.

A Global Impact with a Local Touch

Today, DLM TAPPI specializes exclusively in protective caps, with 55% of its production exported abroad and a significant portion of the remaining products sold in Italy also reaching international markets.

Federtec, representing the Italian fluid component industry, reported that over 60% of the national production of fluid components crosses borders, highlighting the company’s substantial contribution to the sector’s trade balance.

ALSO READ: ISO 50001 CERTIFICATION: A MILESTONE IN ENERGY MANAGEMENT

Green Commitment: Reducing Environmental Impact

DLM TAPPI’s green turn goes beyond product innovation.

The company has invested in 25 new hybrid injection molding machines, resulting in a 30% reduction in energy consumption per kilogram of processed material.

Additionally, modern refrigerators, compressors, and 300 KWp solar panels now contribute to 35% of the company’s energy needs.

These measures have decreased electricity consumption from 3.17 kWh/kg to 1.99 kWh/kg, showcasing the company’s commitment to environmental sustainability.

Conclusion

DLM TAPPI’s green revolution demonstrates that sustainability and industrial efficiency can go hand in hand.

The company’s proactive approach in adopting eco-friendly technologies and materials reflects a dedication to reducing its environmental footprint while maintaining high-quality production standards.

NEED MORE INFORMATION?

CONTACT US