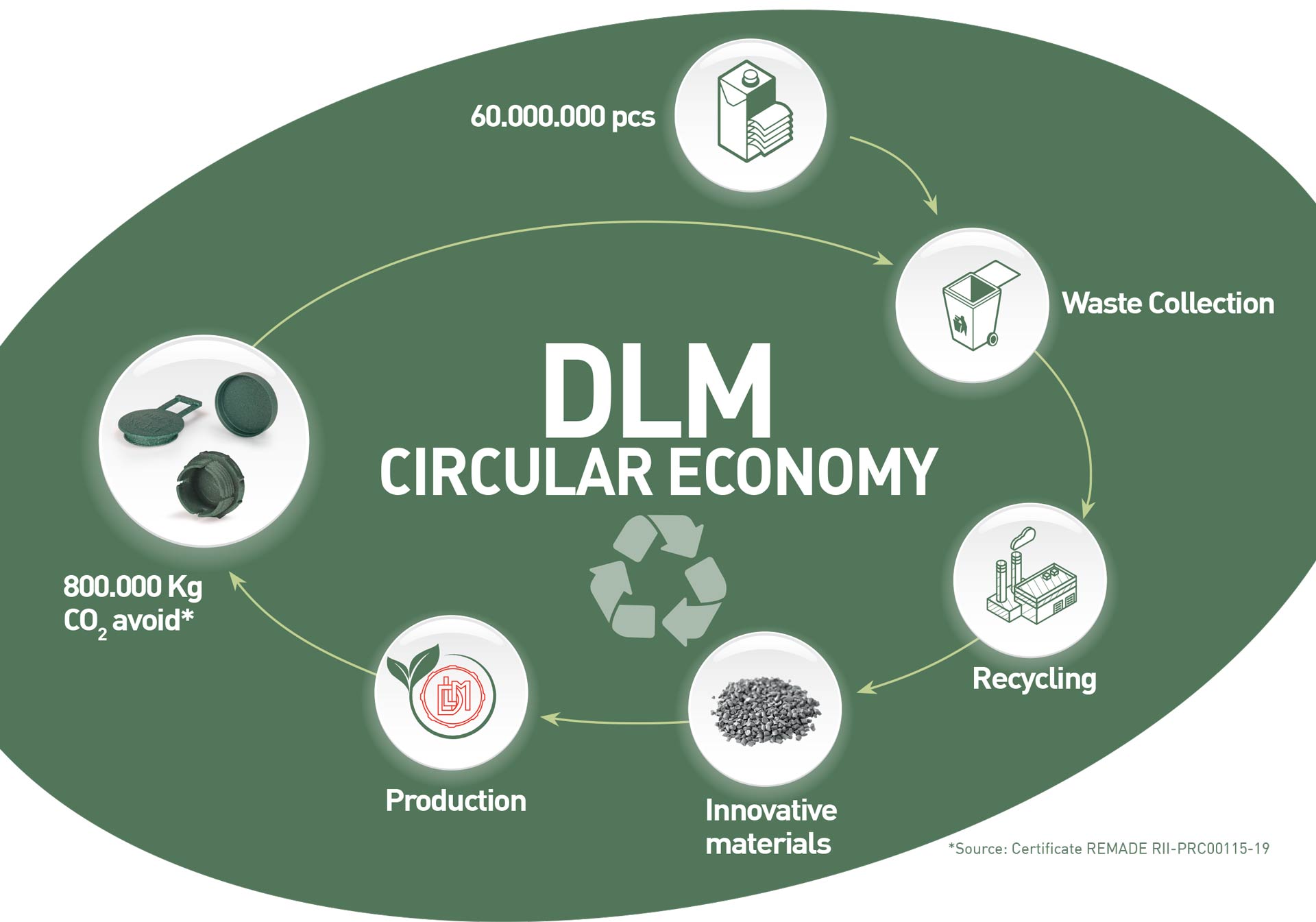

DLM has specialized in the production of protection systems for over 50 years.

The company is committed to ensure a total ecological transition of its products and production processes by 2025.

DLM’s staff is the beating heart of this amazing ecological transition, which turns into actions on both professional and personal level.

Our ecological transition is a concrete commitment to our families, our children and future generations, in order to reduce the environmental impact of our products and processes, which lies on the reliable DLM GREEN DEAL.